| Standard Configuration | Specification |

|---|---|

| Machine Alignment Capability | >2 Cpk +/- 12.5μm, 6 Sigma # |

| Process Alignment Capability | >2 Cpk +/- 25μm, 6 Sigma # |

| Core Cycle Time | 20 secs |

| Maximum Print Area | 510mm(X) x 508.5mm(Y) |

| Printer Construction | One piece optimized welded frame |

| ISCANTM Machine Control | Motion control using CAN BUS network |

| Operating System | Windows XP |

| Operator Interface | Colour TFT touch screen display, keyboard and trackball with DEK Instinctiv software |

| Camera | Green digital camera, using IEEE 1394 interface |

| Camera Positioning | Rotary motors and encoders with 4 micron resolution |

| Squeegee Pressure Mechanism | Software controlled, motorized |

| Stencil Positioning | Manual with screen depth adjuster |

| Stencil Alignment | Motorised via actuators X, Y and Theta |

| Squeegee | Clamped double training edge squeegee |

| Machine Interface | Upline and downline FMI included |

| Connectivity | RJ-45 LAN and USB2 |

| Tri Colour Beacon | Programmable with audible alarm |

| Standard Configuration | Specification |

|---|---|

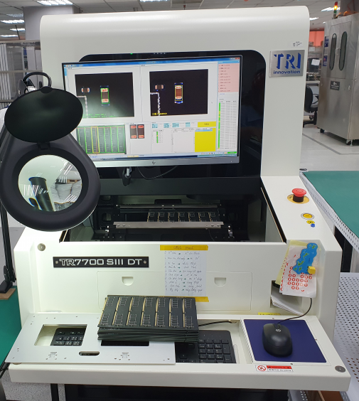

| X/Y Pixel Resolution | 20μm |

| Measurements | Volume, Height, XY Position, Area |

| Height Range / Resolution | 0 ~ 450μm / 0.4μm |

| Height Repeatability | +/- 1% |

| Volume Repeatability | +/- 1% |

| Height Accuracy | 2μm |

| Gage R&R | < 10% |

| XY Servo Linear Motor Resolution | 1μm / pulse |

| XY Servo Linear Motor Accuracy | +/- 5μm |

| PCB Size | 50x50~330x250 mm |

| PCB Thickness | 0.4 ~ 7.0mm |

| Machine Dimension | 705 x 1200 x 1540 mm |

| Standard Configuration | Specification |

|---|---|

| PCB Size | L50mm x W50mm ~ L750mm x W550mm |

| PCB exchange time | 4.4Sec |

| Electric source | 3-phase AC 380V 2.5KVA |

| Machine Dimension | 1280 x 2322 x 1444 mm |

| Mass | 2250kg |

| Placement heat | 16-nozzle head / 12-nozzle head / 8-nozzle head |

| Placement speed | 35000cph / 31250cph / 20800cph |

| Placement accuracy(Cpk>=1) | +/- 40μm / +/- 40μm |

| Component Dimensions | 01005” ~ 12x12x6.5mm / 01005” ~ 32x32x12mm |

| Component supply | Taping : 8 ~ 72mm Stick: 7 ~ 14 Tray: Single tray: 20 |

| Standard Configuration | Specification |

|---|---|

| Atmosphere | Air or Nitrongen |

| Conveyor Speed | 10-60 in/min / 25-152cm/min |

| Conveyor Width | 2-18 in / 51-457 mm |

| Heated Length | 100 in / 2540 mm |

| Heated Zones(Top/Bottom) | 8 top / 8 bottom |

| Cooling Length | 28 in / 711 mm |

| Cooling Zones(Top/Bottom) | 1 top / 1 bottom |

| Overall System Length | 183 in / 4648 mm |

| Overall System Height | 60 in / 1524 mm |

| Overall System Width | 60 in / 1524 mm |

| Voltage Range | 208 – 480VAC |

| Standard Configuration | Specification |

|---|---|

| Optical and imaging system |

1 Top-view camera: XGA 3CCD color camera( 1024x768) Lighting: Ultra-low angle, multi-segment RGB LED lighting system + coaxial lighting Optical Resolution: 20μm Imaging Method: High-speed dynamic imaging |

| X-Y Axis Resolution | 1μm |

| PCB Size | 50 x 50 mm ~ 400 x 300 mm |

| PCB Thickness | 0.6mm ~ 3mm |

| Max. PCB Weight | 3kg |

| PCB Carrier / Fixing | Manual input & mechanical auto clamping |

| Clearance |

Top: 25mm Bottom: 40mm Edge: 3mm |

| Machine Dimensions | 800mm x 1272 mm x 1417 mm |

| Weight | 308kg |

| Voltage Range | Single phase 220~240V 50/60Hz 2.0KVA |

| Standard Configuration | Specification |

|---|---|

| Valid cutting size | 350 x 300 mm |

| Cutting function | Offset to straight line, circular, arc |

| Process table | Dual tables |

| Repeat precision | +/- 0.01 mm |

| Cutting accuracy | +/- 0.02 mm |

| Max. moving speed | XY axes 800 mm/s , Z axis 350 mm/s |

| Max. moving trip | X: 810 Y: 370 Z:90 mm |

| Main shaft rotational speed | Max. 60000 rpm Adjustable |

| Cutting speed | 0 ~ 100 mm/s Adjustable |

| Operation interface | Windows XP |

| Program teaching mode | Color CCD image input by intuition teaching |

| Program backup | USB interface |

| Control method | PC BASE precise three axes control system |

| XYZ axis driving mode | Server motor |

| Adapt to mill size | Φ0.8 ~ 3.0 mm |